Image  Microwave Extraction (Milestone Ethos SEL with controllers)Principle: The Microwave Extraction procedure uses microwave energy to produce elevated temperature and pressure conditions (i.e., 100 -1150 C and 50 - 175 psi) in a closed vessel containing the sample and organic solvent using less solvent and taking significantly less time than the Soxhlet procedure. Applications: Extraction of sample matrices including soil and sediment. |

Image  Accelerated Solvent Extractor (Dionex)Principle: Accelerated solvent extraction, or ASE, is a new extraction technique that is similar in principle to Soxhlet extraction, but the use of elevated temperature and pressure with ASE allows the extraction to be completed within a short time and using less solvent and labor. Uses elevated temperatures (40–200 °C) and pressures (500–3000 psi) accelerates the extraction process. Applications: Extraction of solid and semi-solid sample matrices. |

Image  Automated Solvent Extractor (VELP)Principle: The Automated solvent extractor can be used to separate a substance or a group of elements (e.g. fat) from solid and semi-solid samples with accurate and precise solution for quantitative and qualitative extractable matter determination according to Randall method (consisting of immersion, washing and solvent recovery)., analyzing up to 5 times faster than traditional Soxhlet as the method uses hot/boiling solvents for extraction. The solid-liquid extraction process removes the soluble components from solids using a liquid solvent. Applications: The main field of application is the determination of the content of soluble products such as fats, detergents, plasticizers and pesticides in food, animal feeds, detergents, rubber and plastic formulas, pharmaceutical products, soil, etc. |

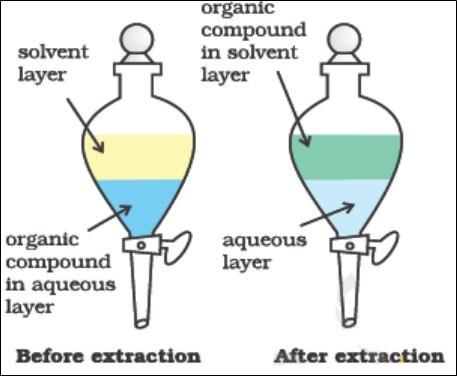

Image  Separatory Funnel ExtractionPrinciple: A separatory funnel is used in liquid-liquid extractions to separate (partition) the components of a mixture into two immiscible solvent phases of different densities. Typically, one of the phases will be aqueous, and the other a non-polar lipophilic organic solvent which form a clear delineation between the two liquids. The two layers formed are usually known as the organic and aqueous phases. Most organic solvents float on top of an aqueous phase, though important exceptions are most halogenated solvents. The organic solvent used for the extraction must not react with the substance to be extracted or with water. It should also have a low boiling point so it can be easily removed from the product. Applications: Extraction of Immiscible liquids & Water. |

Image  PARALLEL EVAPORATOR (BUTCHI)Principle: Operating is based on fast sample evaporation by heating, orbital shaking and vacuum application of multiple samples. Closed sample vessels/tubes with sample solution or extract are placed inside glass cylinders filled with water on the Multivapor evaporation plate. Subsequently the required evaporation temperature, orbital movement and (optionally) vacuum conditions are applied, and fast extraction starts. With the help of the vacuum gradient function of the Vacuum Controller V-855 smooth adjustment to the end-vacuum is possible. This function is also ideal for evaporating off solvent mixtures which typically accumulate after chromatography. Applications: Sample preparation after extraction, Simple distillation. |

Image  TurboVap Concentrator (Zymark)Principle: TurboVap is used for evaporation of large volumes of solvent after extraction. It is a microprocessor-controlled concentrator used for sample preparation that provides unattended, automated sample evaporation. It uses a patented gas vortex shearing action and optical sensors to provide fast and efficient evaporation of organic solvents. Optical sensors automatically stop gas flow when evaporation has reached its set time, thereby eliminating the risk of drying and loss of volatile compounds. Applications: Sample preparation for GC Analysis after extraction. |

ULTRASONIC BATH (Grant)Principle: Ultrasonic bath uses cavitation bubbles induced by high frequency pressure (sound) waves to agitate a liquid. The agitation produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates blind holes, cracks, and recesses. Applications: Sonication & extraction of ions from filter papers. |

Image  Hydrolysis Unit HU-6Principle: The ideal solution for the sample preparation prior to solvent extraction for the determination of the total fat content, in order to free the fat molecules ready for extraction. It is complete safety and handles six samples at the same time in order to maximize productivity. Applications: the ideal solution for the sample preparation prior to solvent extraction for the determination of the total fat content, in order to free the fat molecules ready for extraction. |

Image  Ultra-Performance Liquid Chromatography (UPLC)Principle: UPLC principle based on the Van Deemter equation that justifies the correlation between flow rate and plate height. This technique uses fine particles (less than 2µm), reduces the length of the column, and saves time, and reduced solvent consumption. Applications: UPLC enables the efficient analysis of active pharmaceutical ingredients (APIs), impurities, and degradation products, facilitating method development, validation, and routine quality control testing. |

Image  CentrifugePrinciple: the centrifugation technique is to separate the particles suspended in liquid media under the influence of a centrifugal field. These are placed either in tubes or bottles in a rotor in the centrifuge. Applications: it used in medical, clinical, pharmaceutical, and biotechnological fields. These centrifuges play a crucial role in separating substances based on density, which is essential for various laboratory procedures. |

Image  Principle: Restek Q-sep products make QuEChERS procedures even simpler. All extraction salts, sorbents, and sample tubes are included. Applications: Fast, Simple Sample Prep for Multiresidue Pesticide Analysis. |

Colored

Colored Grayscale

Grayscale